Objectives of the project .

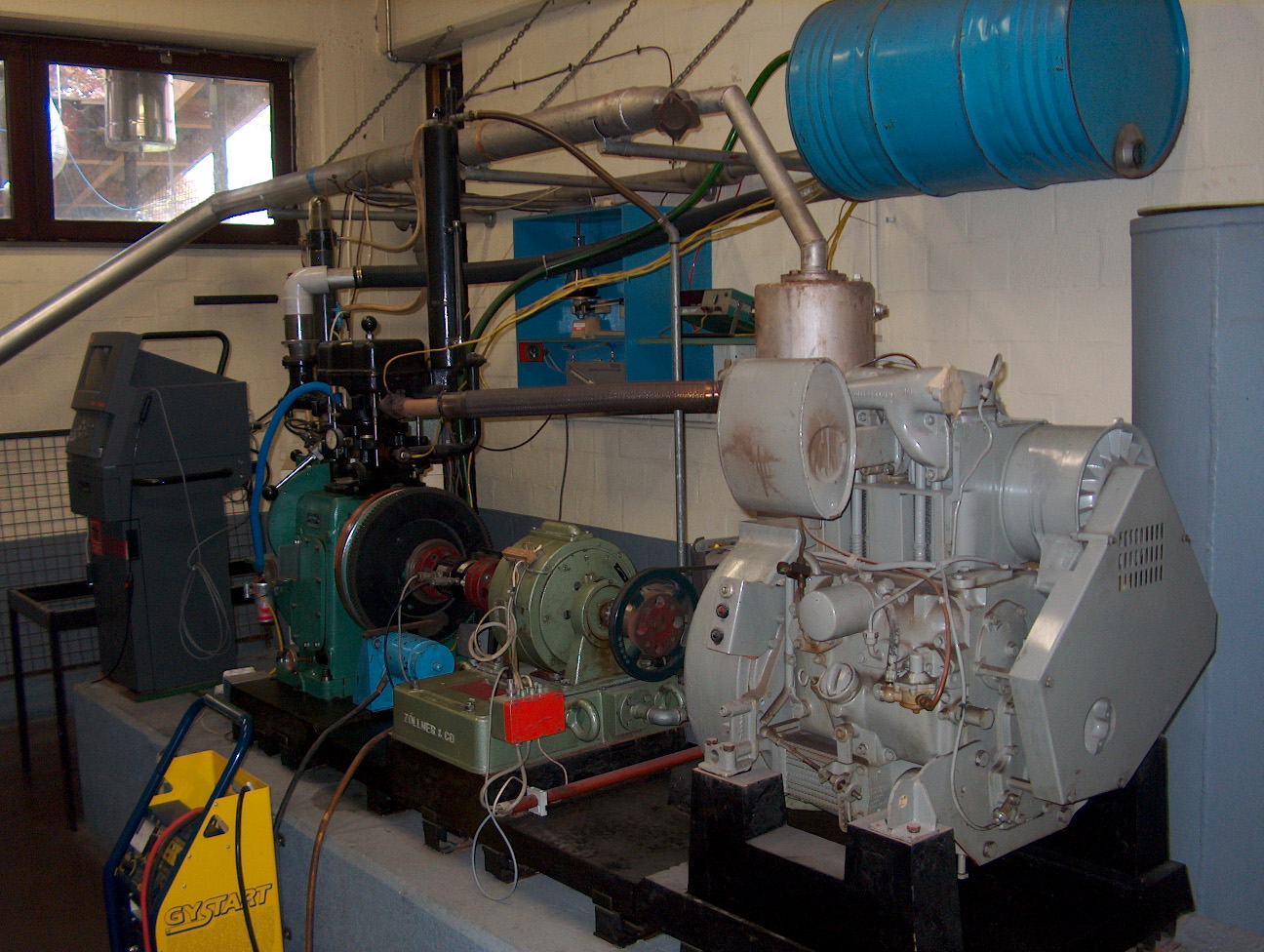

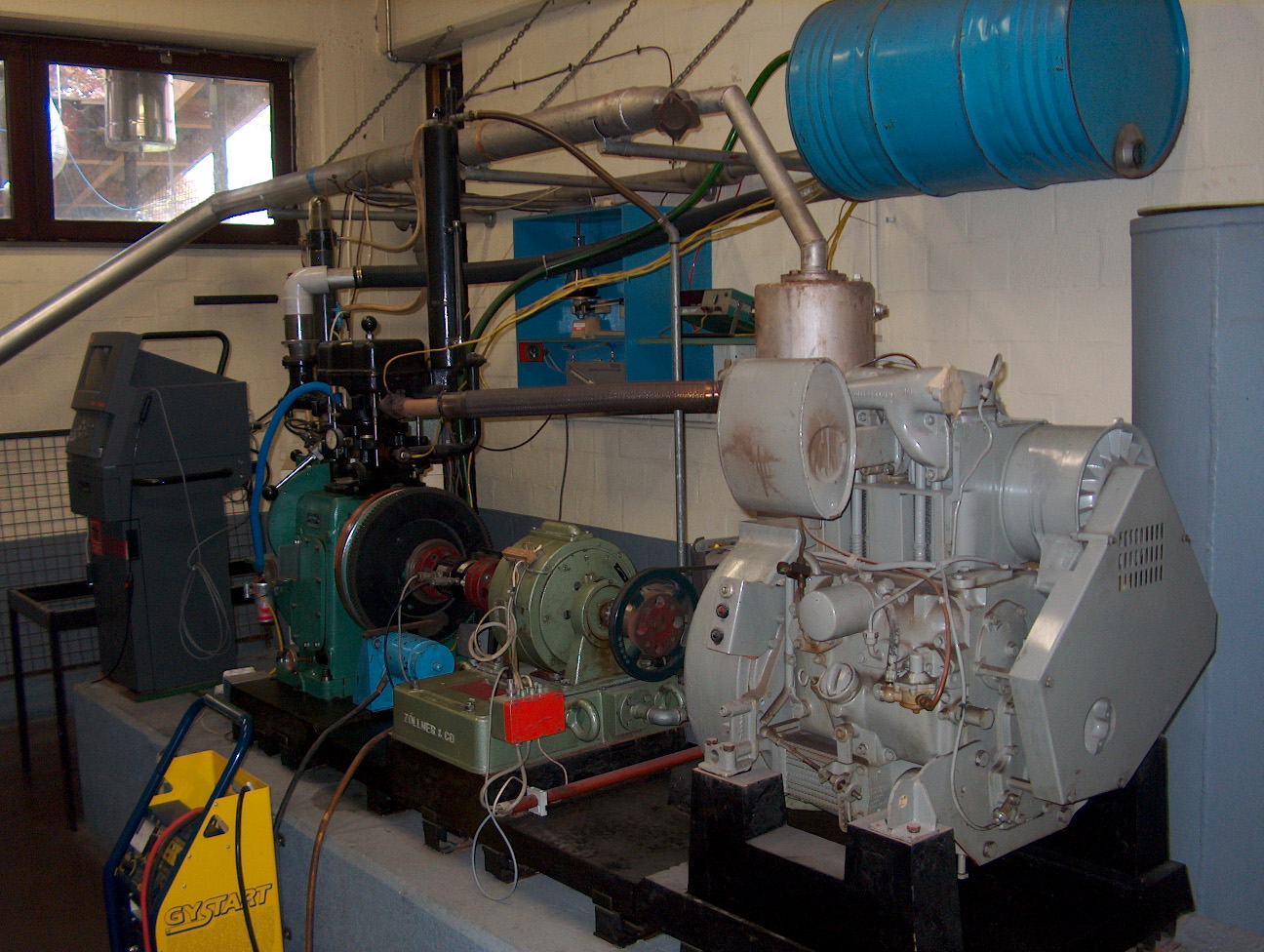

In the labo of the department electromechanical engineering , there is an engine which is used by the students of the 4th year electromechanical engineering for the practica for the course “Combustion Engines” . This engine is a CFR-48 , which has very special characteristics and was designed to test the quality of all kinds of fuels . It consists of only 1 cylinder and an ignition spark is provided . It is possible to modify the compression ratio as well . This way , either diesel and gasoline can be tested . The fuel is supplied trough injection . Also , the pre-ignition-angle can be adjusted and the supply of air and fuel can be controlled individually . This way , it is possible to test all kinds of fuels with different properties and of different qualities .

In order to make a qualitative and quantitative evaluation of the results , different parameters are measured . Amongst those parameters are the torque , produced by the engine , and the number of revolutions . The torque is measured by a torque sensor and the number of revolutions is controlled trough a PID-regulator . The problem with the values of these parameters is that they aren’t very reliable . The RPM (number of revolutions) is returned on an analog meter , but the resolution of the scale isn’t satisfying . The torque is returned on a display , but only the instantaneous value is returned . Unfortunately , there is a very strong fluctuation on the values of the torque , which makes it very hard for the students to determine the mean value of the torque . Our task was to design and program an electronic circuit , which calculates the mean value and the standard deviation of the torque and the number of revolutions , and to return the achieved values on a display .

The CFR setup