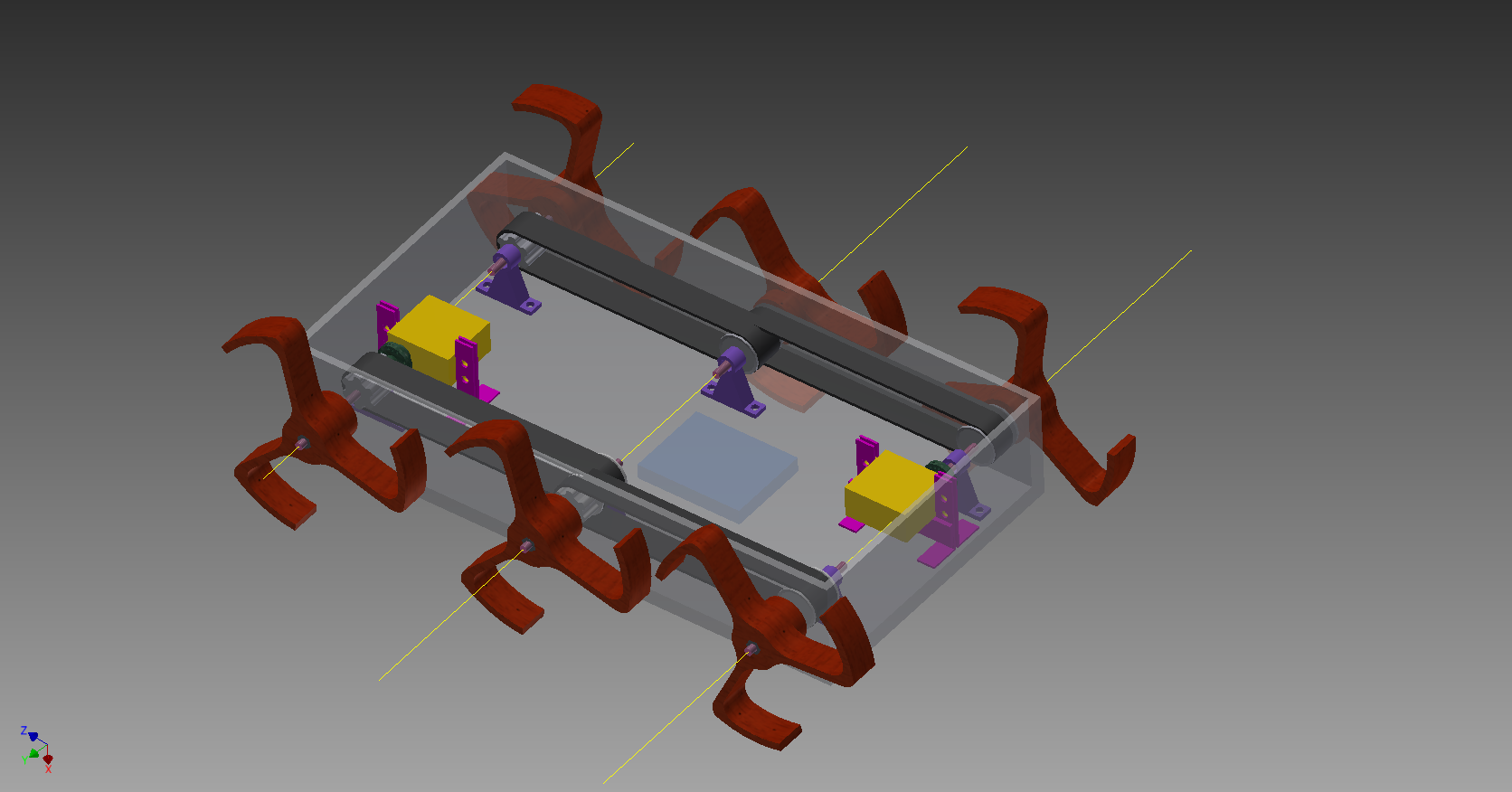

Global Design of the Robot

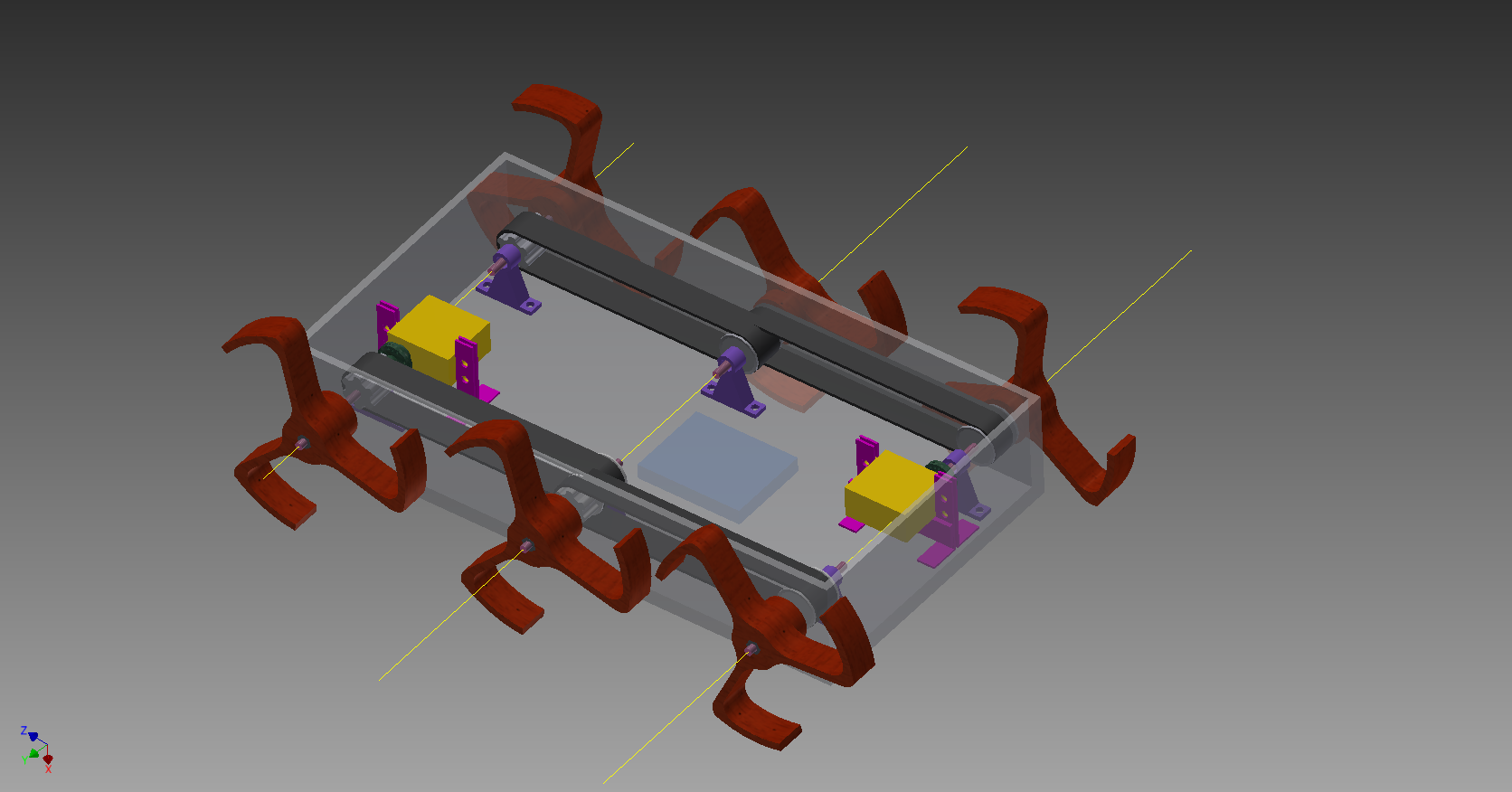

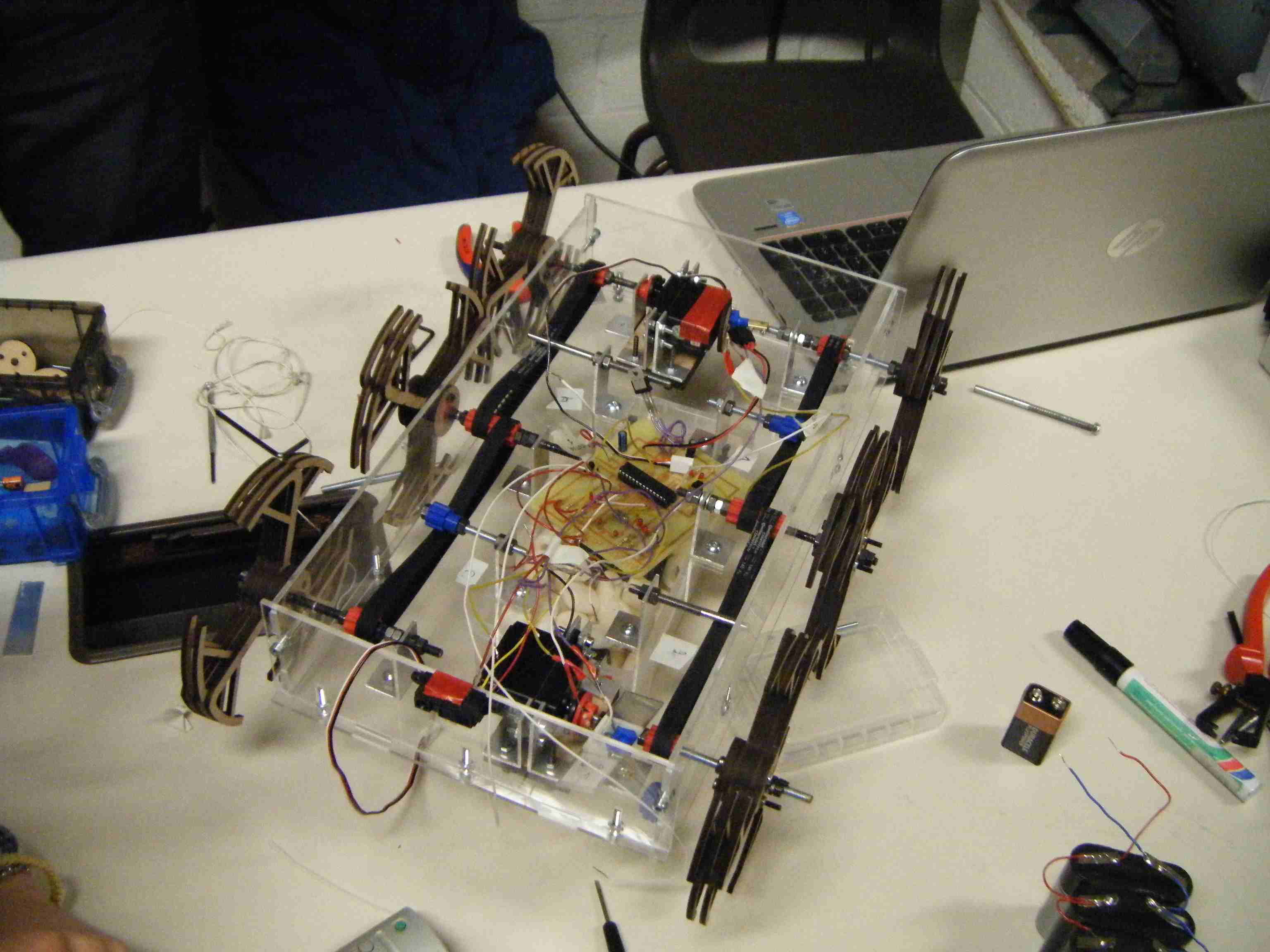

The total assembly |

The global design of the robot is shown on the figure.

The robot has 6 Whegs (developed in the next section), actuated by 2 motors (one for each side).

The Whegs are fixed to rods and the Whegs of one side are connected together via belts.

A box in Plexiglas compose the body of the robot in order to fix the motors, the actuators and to have better motion of the Whegs.

The geometrical characteristics and components of the main parts of the robot are explained in the next sections.

The Whegs

The Whegs |

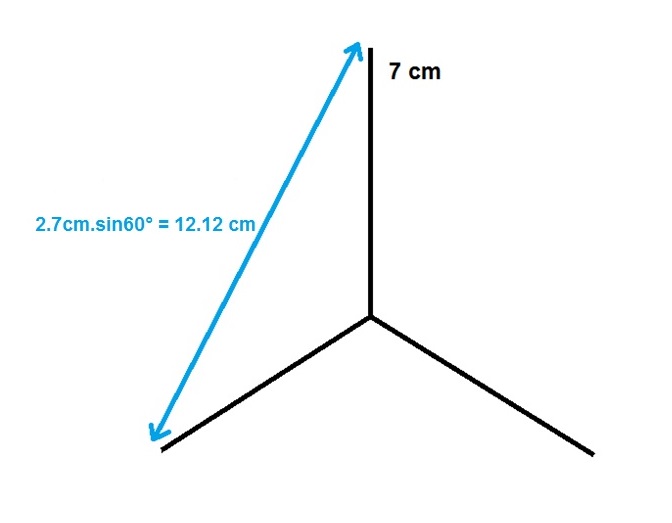

The Whegs robot was initially inspired on a cockroach movement.

“Whegs” is a combination of wheels and legs and these robots are specially

designed to overcome relatively large obstacles. They can even overcome obstacles

with a height of 175% of the length of the legs. The legs of this robot

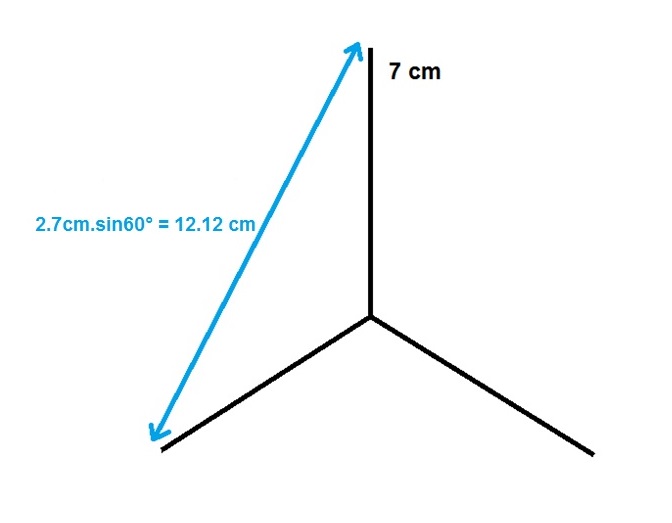

have a length of 7cm, this means they can overcome obstacles with a height of about 12cm.

This distance corresponds to the distance indicated in blue on the figure.

Some fillets are applied to better distribute the stresses in the legs.

Since the multiplex plates are only 3mm thick, multiple plates are put together to ensure the strength of the Whegs made in this material.

Also, extra circular plates are added around the rod to create a spacing between the box

and the legs.

The first idea was to use already existing Whegs, but these were not found.

Then, the idea to produce special Whegs for this robot was chosen.

Indeed, it was possible to use wood or Plexiglas and laser cutting machine (instead of 3D printing giving less strong results).

The Design of the Whegs was done by the team, in order to have 3 main legs, with curved end to ensure a better ground contact.

THe Whegs has to be fixed in a particular manner, as it is explained in the section "Actuation: Specifications".

The L profiles

The motors are strongly fixed to the box thanks to L profiles made in Aluminium (for lightness and strength).

The same aluminium L profiles are also used to support the rods of the Whegs.

A same design is used in order to reduce the manufacturing costs and time.

The box

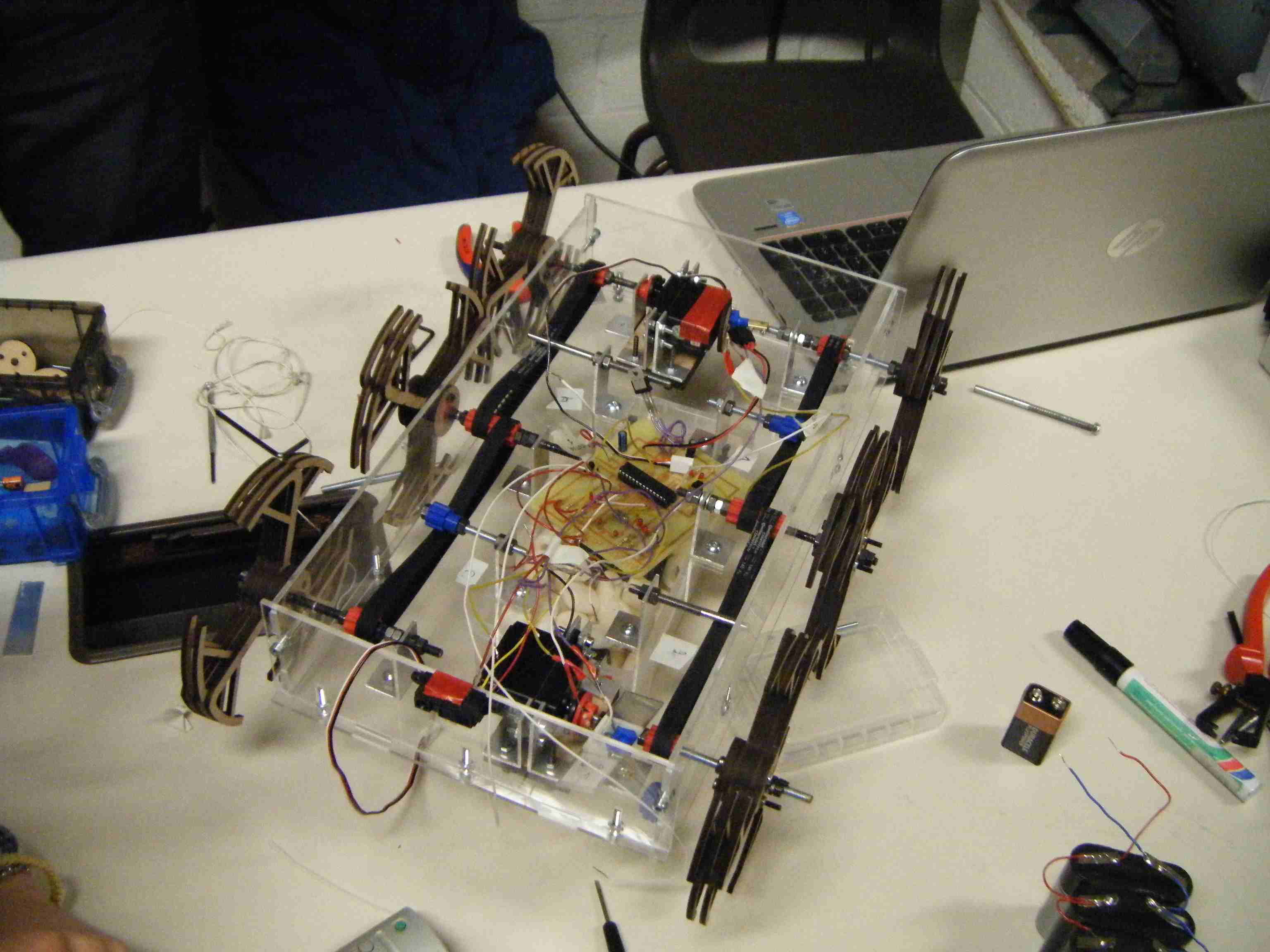

The Whegs |

The box is made out of six Plexiglas plates that are connected with screws has shown on the

picture. This method allows a quick, easy and strong assembly.

The plates were firstly designed on Inventor before the use of the laser cutting machine.

The position of the holes (and their dimensions) are really accurate thanks to this manufacturing process.

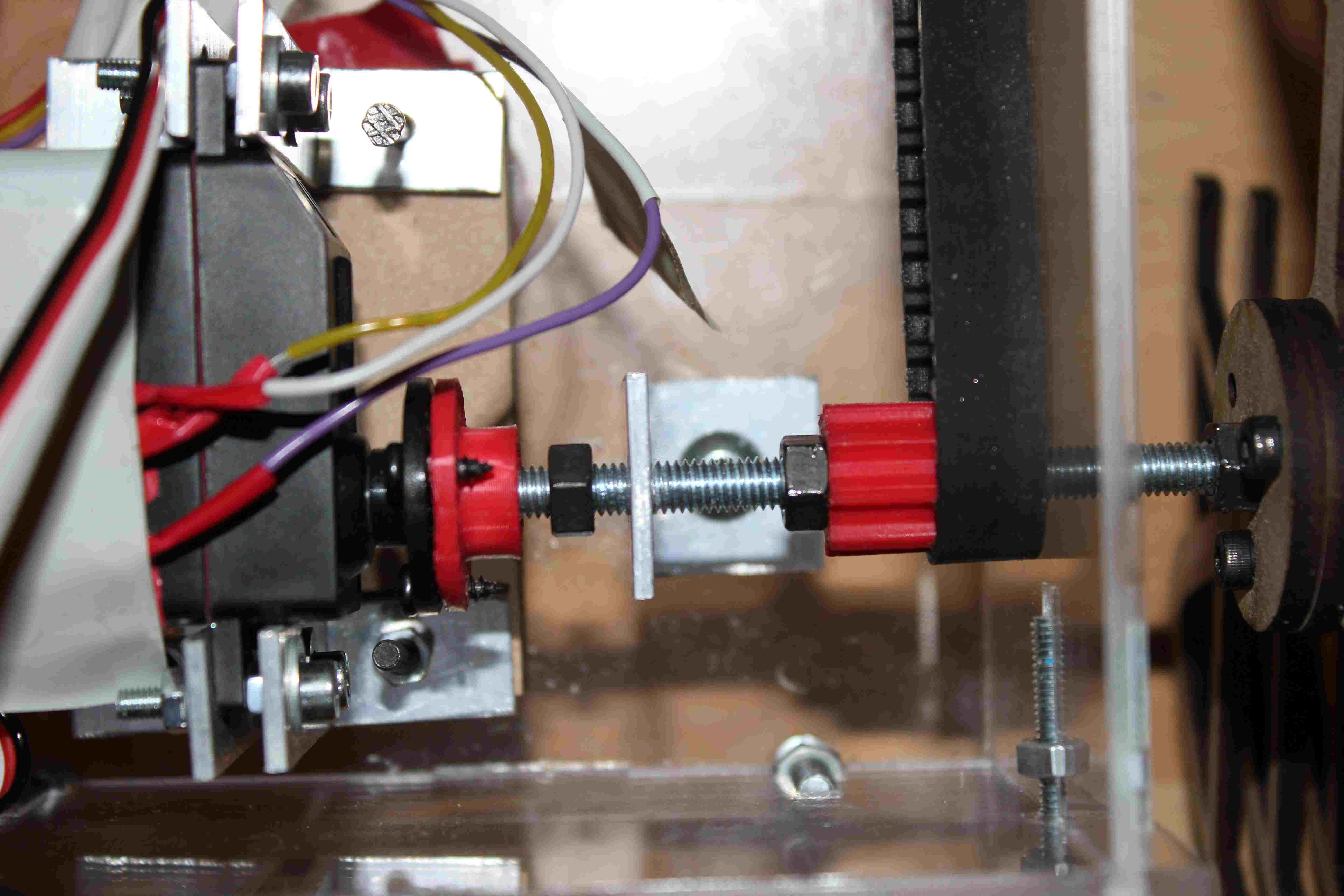

The belt system

The Whegs |

The Whegs are actuated by means of a belt system.

The motor is directly connected to one of the Whegs, which drives the middle Wheg. This middle

Wheg is then connected to the remaining Wheg by another belt. Thus, each side has two belts.

The gears for the belt system are made using 3D printing and are screwed on the rods.

The design of these gears was made by the team. The length and the number of teeth of the belt

were taken in account. The height of the teeth is an important parameter to determine the height and the

width of the teeth on the gear. Finally, the ratio between the length of the belt and the perimeter of the

gear is another really important parameter. This value was calculated based on the maximal rotation speed of the

robot that was expected.

The motor and one rod (then one Wheg) are strongly connected via special wheels.

The small wheel connected to the motor was sold with the servomotor. The connection between

these two components is therefore easy and efficient. The connection to the rod is not so easy.

A wheel was designed and printed in 3D to fix the two wheels together. The printed wheel was attached to

the rod by mean of an auto-blocking bolt.

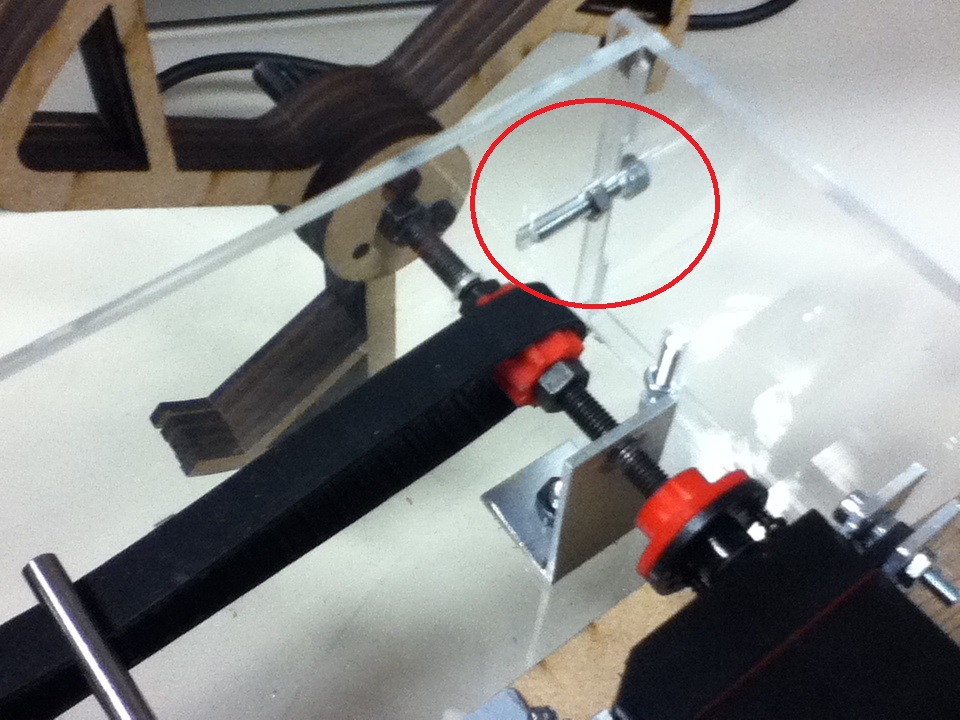

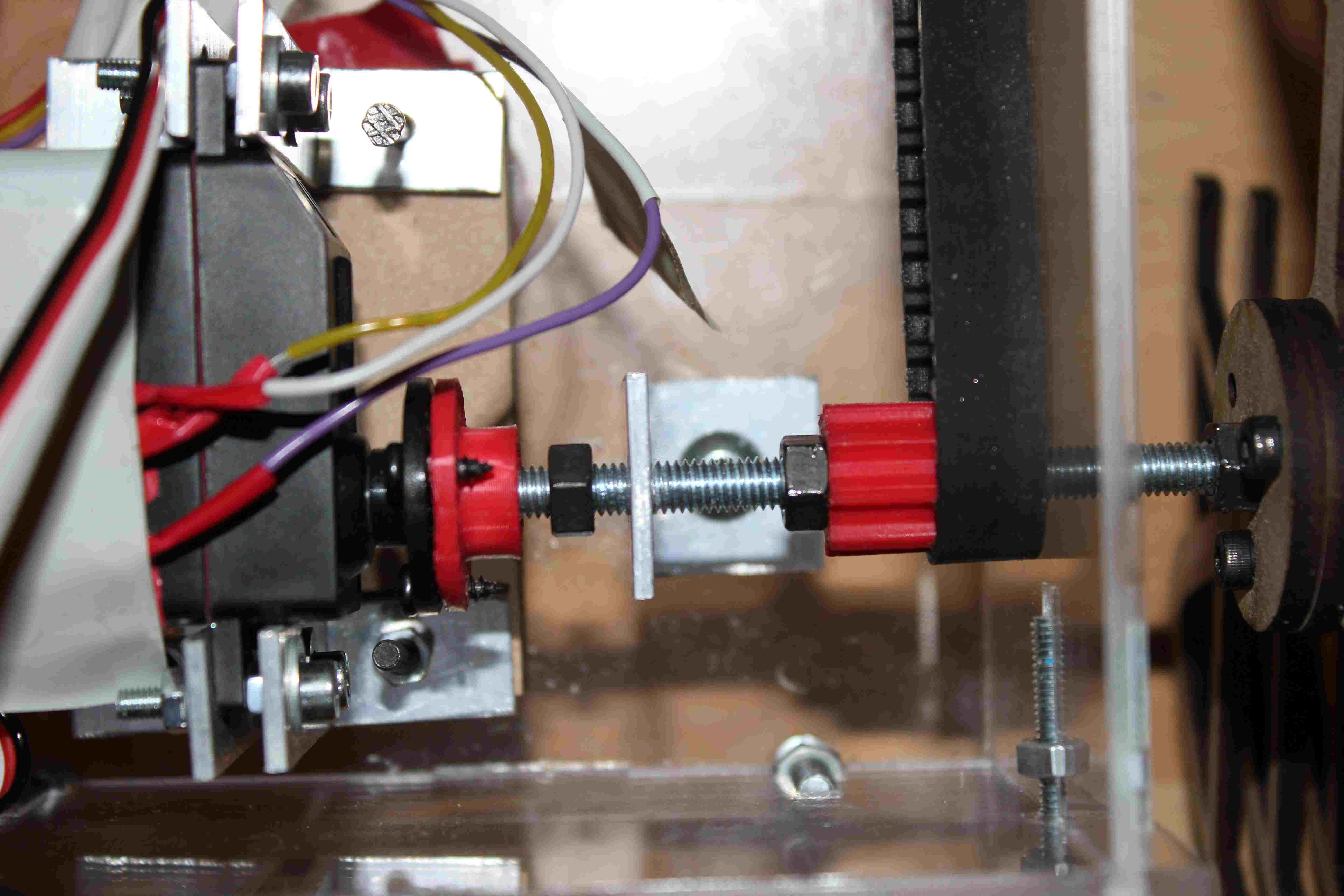

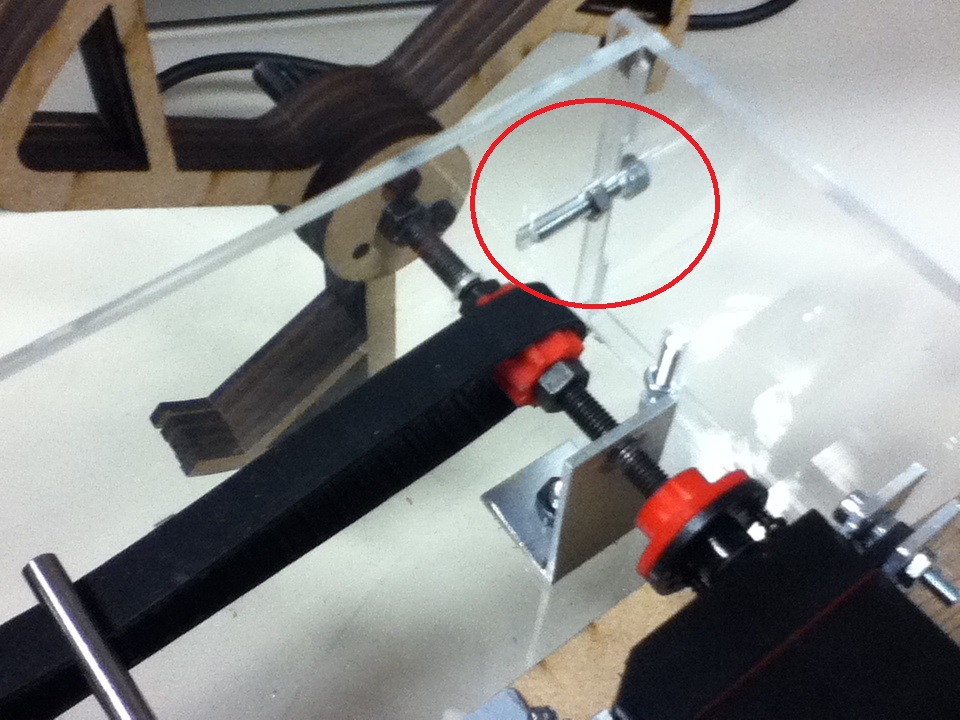

Rod

Connection to the motor |

The Whegs are fixed on a rod with an M5 thread at the end. This thread makes it possible

to connect the Whegs to the rod using a nut (NL:moer, FR: écrou). The rod of one of the outer Whegs is also connected

to the motor. The connection pieces are made using 3D printers and a close-up is shown in the picture.

Back to Top

The Whegs-Robot Team

The Whegs-Robot Team