The Motors

When calculating the torque the motors should be able to deliver, only the contact of the Whegs with the

ground is taken into account. But tensioning the belt means that the motors should also be able

to overcome the friction caused. Since this friction is quite high and the motors are not chosen to

overcome this friction, they are not powerful enough to move correctly the belts tensioned.

To reduce this problem, the belt tension is reduced. By doing this, a lot of power is lost and

the Wheg that is furthest from the motor will turn more slowly.

The possible improvements of this part of the robot could be to find better motors delivering a higher torque (or higher

rotation speed, and then use a gearbox). Another solution could be to improve the distribution mechanism.

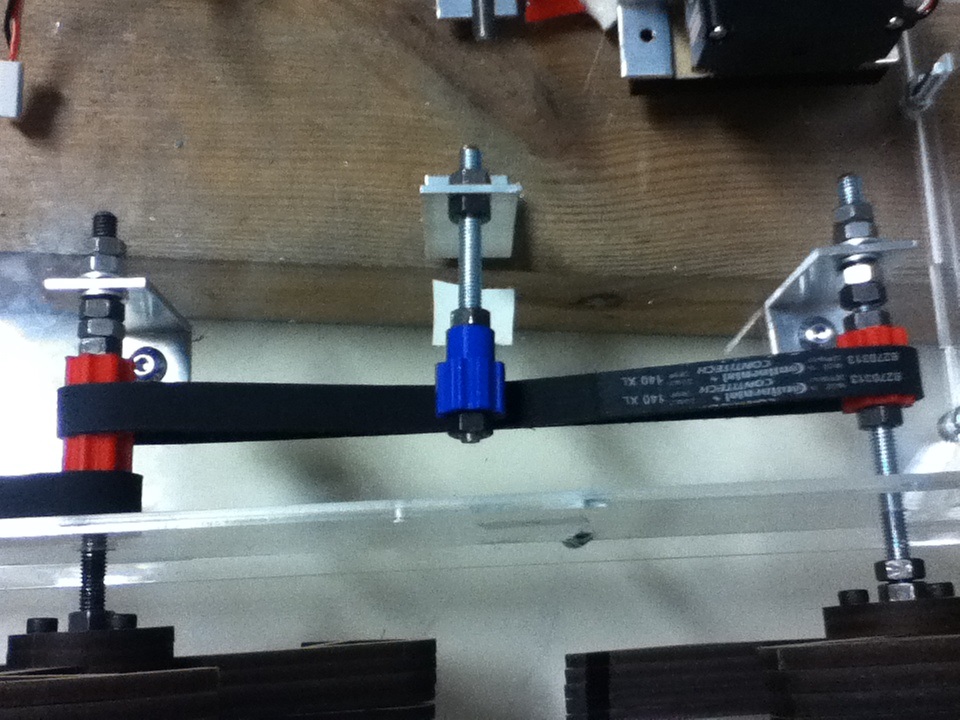

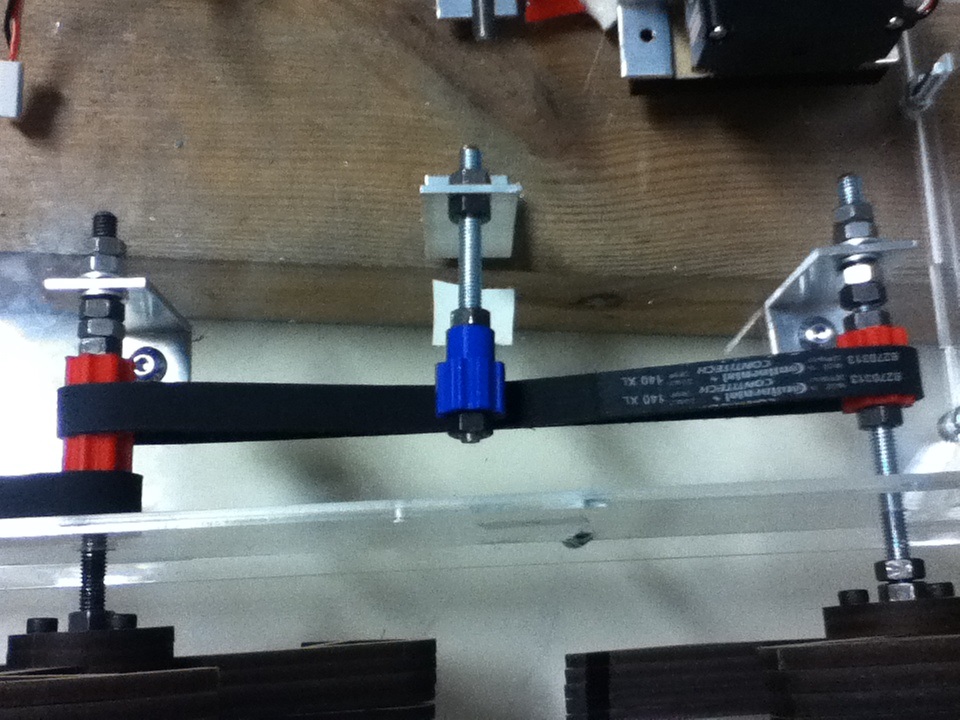

The tensioning of the belts

Tension roller |

When choosing the belts, the length seemed a perfect fit with the robot design. But, when installing the belts

however, they appeared to be too large. Thus, tension rollers were needed. To add these tension rollers, extra

holes were made in the plexiglas plates. The result afterwards was that the belts were tensioned better, but the

tensioning was not perfect. To overcome this problem, adjustable tension rollers could have been used. For instance,

the use of spring to control automatically the tension of the belts could be a nice improvement.

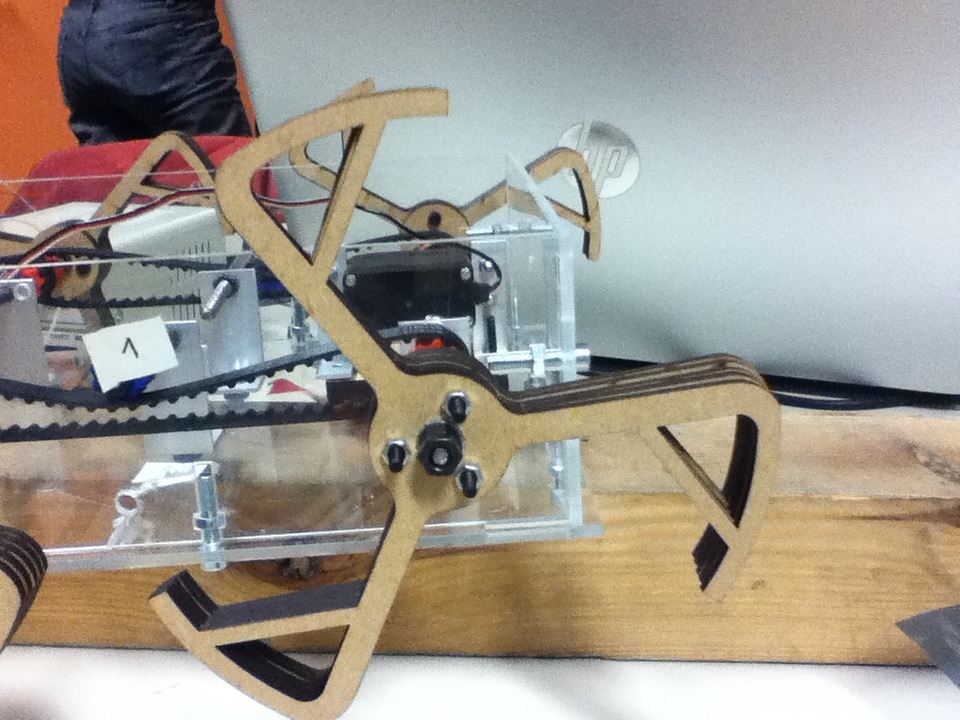

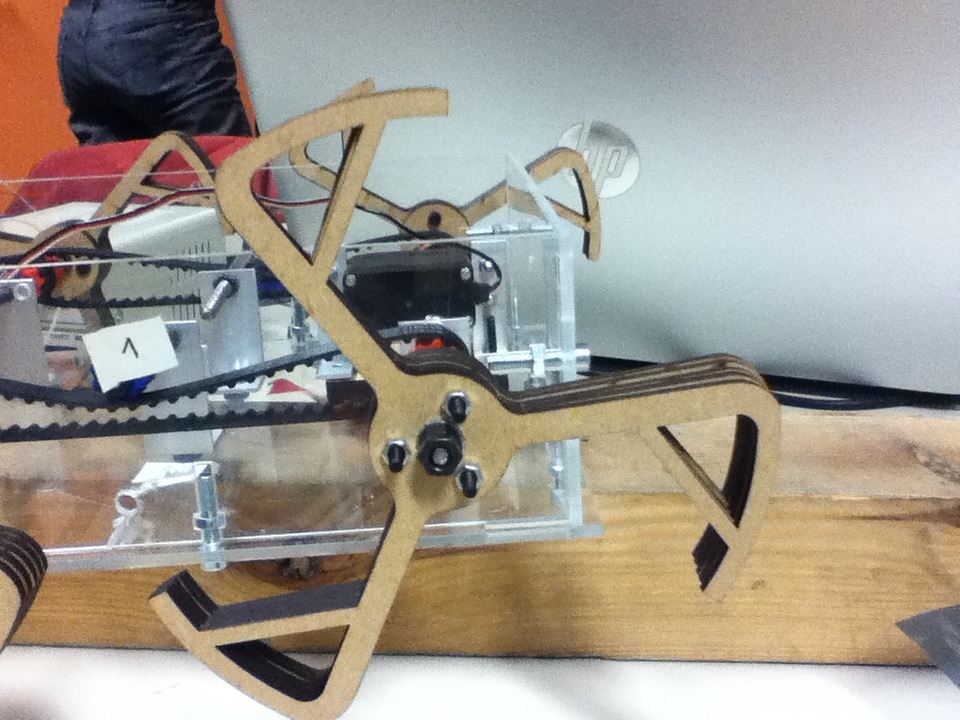

The Whegs

The original idea was to give the robot a sort of L shaped Whegs (for more information see the page

'Design of the robot'). These are well suited to overcome obstacles

when moving forward. The motors, however, are not powerful enough to overcome the large gap in the Whegs. To make the robot move, the

multiplex plates, where the Whegs are made of, are placed in a symmetric configuration to reduce the

gap (Symmetric should be understood here as having "triangular" in stead of L shape Whegs). Although smaller, there is still a gap present, which makes it possible for the robot to overcome

obstacles higher than the radius of the wheels.

Another advantage of this symmetric configuration is that there is no longer a difference in moving backward and moving forward.

The original Whegs |

The symmetrical Whegs |

The L-profiles

The L-profiles are used to support the rods. Because the rods are threaded however,

the rods do not turn smoothly when supported by the L-profiles. This could be

improved by removing the thread of the rod where there is contact with the L-profile.

Another possibility is to use bearings instead of L-profiles to support the rods.

The Control of the Rotation

The control on the rotation of the Whegs used in this project is based on the use of encoders connected

to the rods (linked to the Whegs). These encoders are placed on the most far Wheg compared to the motor position.

As the tension of the belt is not sufficient, this Wheg has a rotation speed a bit lower than the wheg connected to the motor.

This difference of rotation speed can make the robot turning when it should go forward.

Furthermore, if some Whegs are slipping in the air or on the ground, the encoder will continue to measure the rotation of the Whegs, even if

no distance are really crossed by the robot. The programming will work normally because it cannot detect this kind of abnormal behaviour.

A solution to these problem could be to use a Gyroscopic sensor on the robot. Indeed, this sensor can inform about the rotation of the robot.

If it should go forward, the behaviour is abnormal and the control on the rotation speed of the motors can be performed, in order

to adapt the speed of the motor turning too quickly of too slowly (in function of the direction of the rotation).

This kind of sensors are a bit more expensive than the encoders used in this project, but could solve the problems described previously.

Back to Top

The Whegs-Robot Team

The Whegs-Robot Team