Mechanics model:

Guidelines

1. Limited dimensions

We wanted to keep the dimensions of the robot reasonable, essentially for aesthetic

purposes.

2. Mobility

The whole assembly should be easily transportable.

3. Sturdiness

The device must resist to a normal use.

4. Good hiding of the electronics

Parts such as wires, PCBs, etc. should be concealed and invisible to the user once the robot

is assembled.

5. Ease of assembly

The assembly had to be kept in mind during the design of all the parts.

6. Reasonable budget

We wished to avoid too much expensive parts.

In order to prepare the design of our robot, the first step was to establish a list of the

specifications that we wished:

Material choices

These requirements being settled, a first design was conceived. Before presenting it, let’s

review the different material choices that were made:

External case

The material chosen for the case is wood. Firstly because of its opaque nature, allowing us

to hide the electronic components inside the case. Since laser cutting was planned to obtain

the parts, we narrowed the research to two possible materials: multiplex or MDF.

Positioning system

As explained in the homepage of this website, the principle of our robot is to write the time

on a surface and erase it continuously. To do so, it has to be able to move the writing

device in two directions. This implied a review of the different 2D-positioning systems that

could be applicable. In other words, we had to find a way to transform the rotation

movement of our motors into a linear motion. Three systems were retained:

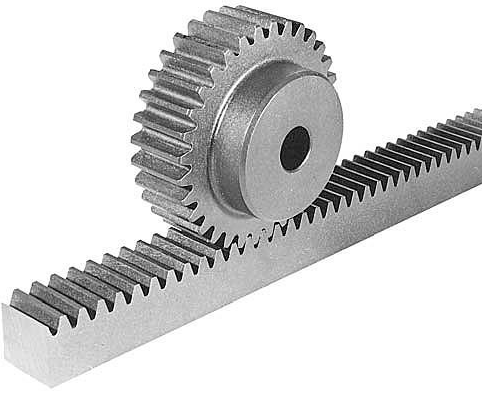

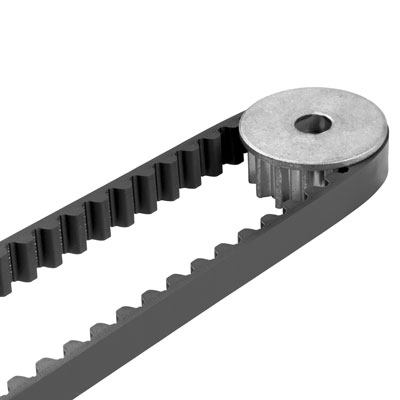

The first system considered is composed

of a conventional spur gear and a rack.

It has the advantage of being quite

compact and its parts are easy to find.

It could even be manufactured by

ourselves (through 3D printing).

1. The gear and rack drive

2. Belt drive

3. Leadscrews

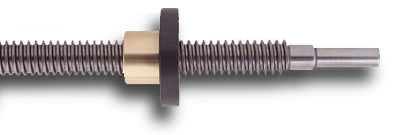

This system has good accuracy but was

quickly abandoned because of its size

and more importantly the cost of its

parts.

We also thought of using pulleys and

belts to achieve the positioning.

Although the slip problem is less

important than for the gear and rack

system, they need more room because

a tensioning system must be added to

ensure its good operation.

Finally, for the first design, we chose the gear and rack system. Indeed, we appreciated

the fact that it was easy to obtain and to place on the structure.

Writing head

After the problem of positioning had been dealt with, we had to find a way to achieve the

up-and-down movement of the writing head on the surface (determining when the tip is

writing or not). Two systems were considered:

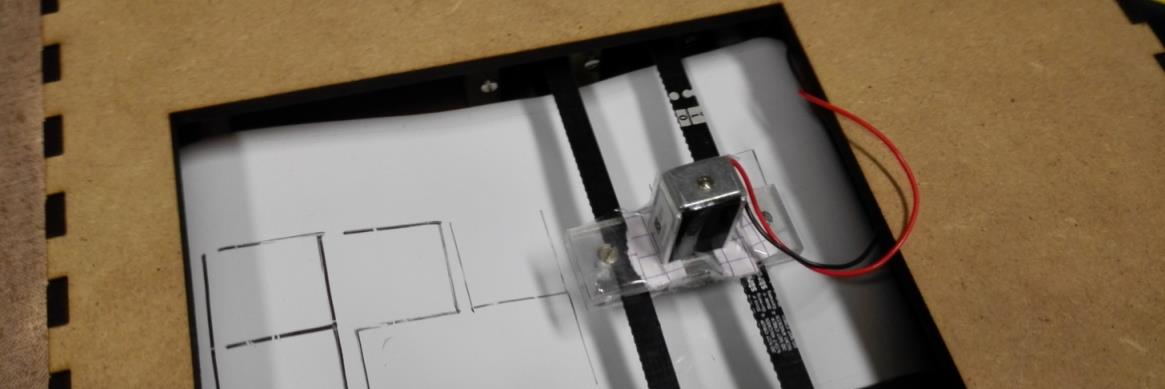

In the end, our choice was to use the solenoid. Its control is simple and its dimensions are

restricted.

1. DC motor/servo/stepper with screw

System consisting in a small motor

connected to a screw shaft. The

writing tip should then be connected to

a threaded part to achieve linear

motion.

The other possibility was to use a

solenoid. This device generates a

magnetic field that is able to push or

pull the metallic shaft. It is more

compact than the previous system.

2. Solenoid

At first, we considered using a piece of a conventional

whiteboard as a support for writing the time.

However, this choice was abandoned to the profit of

“whiteboard film”, a flexible writing surface

presenting the same characteristics as a whiteboard.

Writing surface

First design

Description

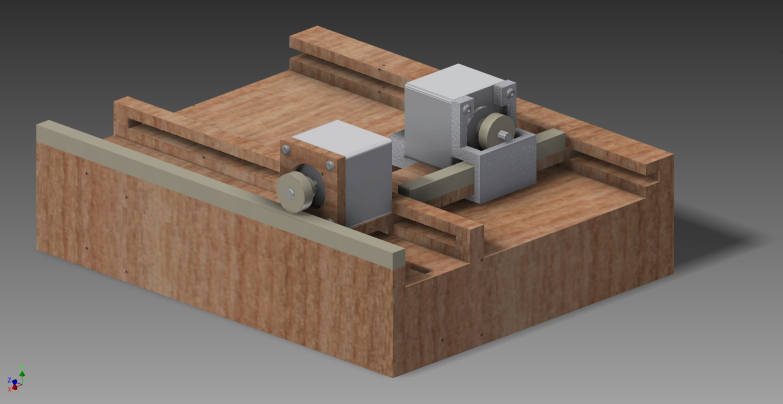

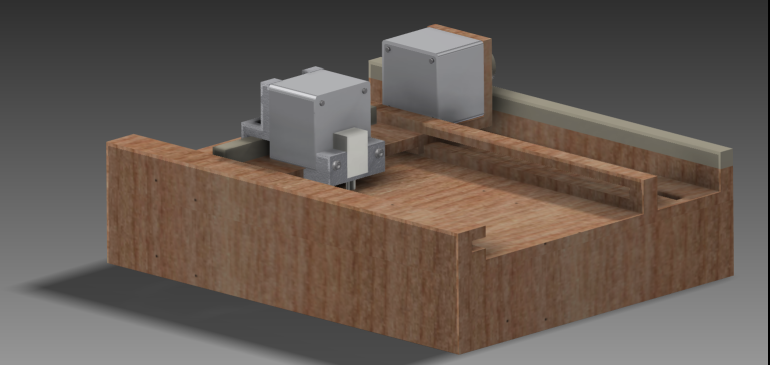

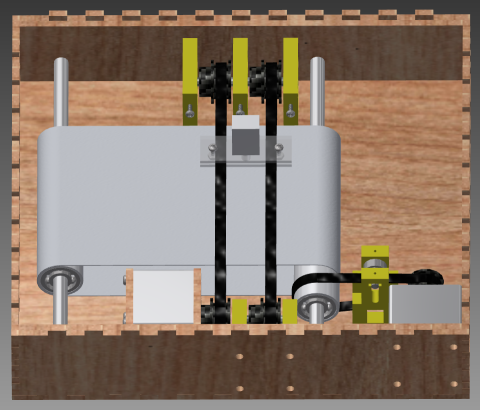

Once the choice of the different components had been made, we could begin the

development of a model. This was done using Autodesk Inventor:

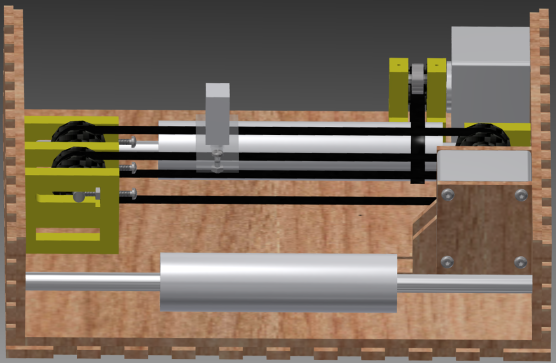

As seen on the picture, the positioning system lies on top of the global assembly. Both the

x-axis and y-axis movements are provided by motors and gear-and-rack transmission

systems. The two motors stand on a mobile wooden part that is guided by “rails” on two

locations. One of the motors is attached by screws directly to the wooden part and the other

is unified to a sliding plastic piece (3D-printed). To hold the solenoid in place, a second 3D-

printed support is considered. To erase the time, a standard whiteboard eraser would be

placed on the stepper support.

Issues

Although this design helped us to get information on the different components available to

realise the robot, it posed four important problems:

Second design

1. Friction

As most of the wood used for laser-cutting have a rough surface, it is

probable that the mobile wooden part would have difficulties sliding on its

rails. A potential solution would be to use another material such as

plexiglas.

2. Only one side of the slider is driven

This could cause the wooden slider to rotate and then to block.

3. Two motors on the slider

This might cause overload on the motors due to the important mass.

4. Assembly problems

For the first design, a screw assembly was considered. This could have

caused issues at some points where many parts must be assembled (e.g.

the bottom part, the cover and the rail).

All in all, these issues (mainly the friction issue) caused us to drop this design and restart

from scratch.

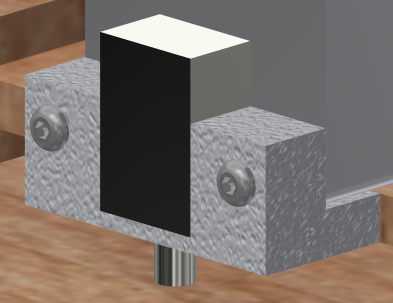

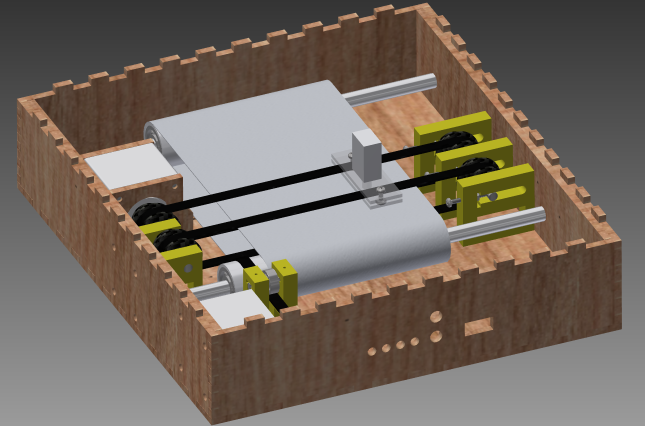

The second concept was designed to avoid the previous problems:

It contains numerous improvements over the first concept:

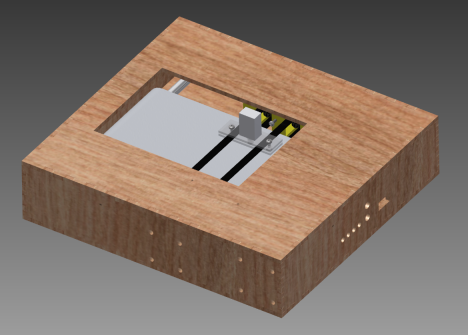

1. More compact

The first thing to notice is that it has been made more compact since now

all the components are in the same space.

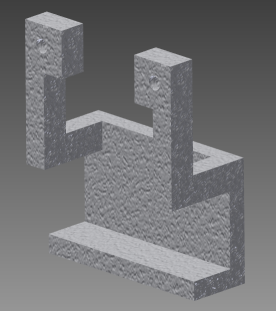

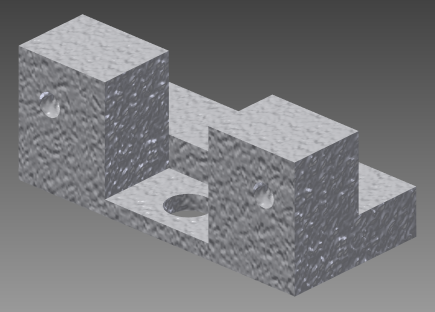

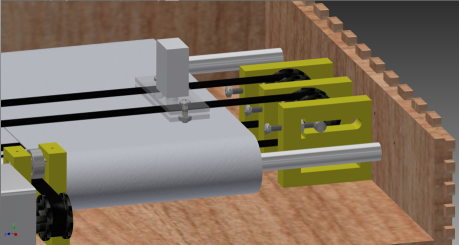

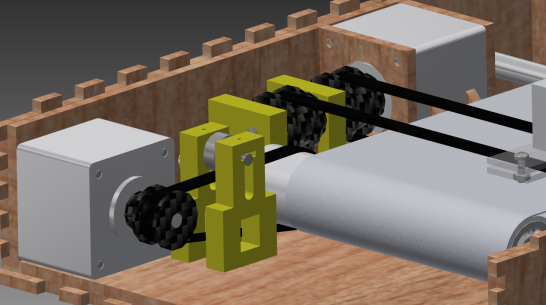

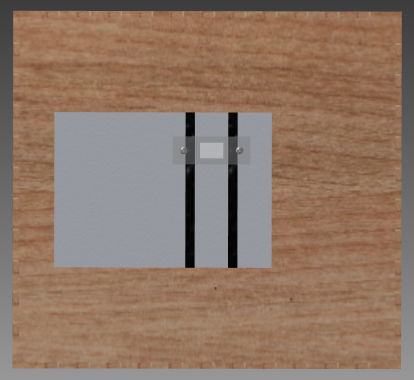

2. Positioning system

Movement along the vertical axis is now ensured by two belts. On these

two belts, a support formed of 3 plexiglas layers is design to hold the

solenoid in place. To adjust the tension of the belts, we imagined a new

system. It is composed of three identical 3D-printed pieces, three bolts and

an axle. The pulleys are mounted on the shaft and it is then possible to set

up their position by screwing the bolts, giving result to more or less tension

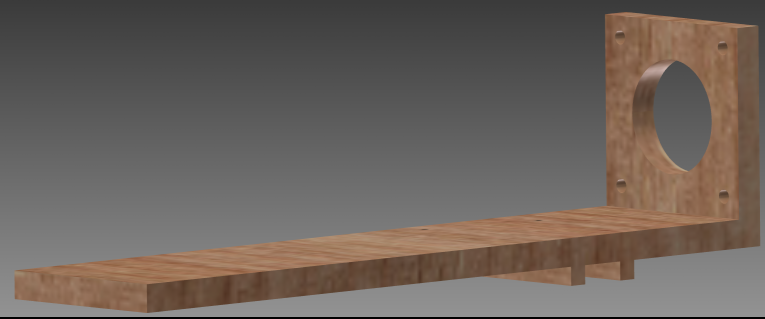

on the belts. For the horizontal movement, two shafts support PVC tubes

(using bearings). Around these PVC tubes, the whiteboard film is rolled. To

achieve the rotation, the stepper motor is connected to the right PVC tube

thanks to a belt. The tensioning system is similar to the one described

above. Note that this time, to erase what is written on the whiteboard

film, an eraser is placed under it.

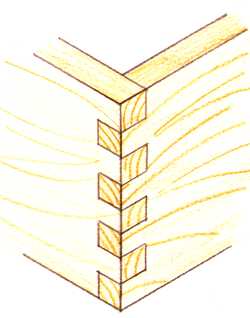

3. External case and supports

The material for the case was kept the same as

before (MDF). However, to assemble the

different panels, a “finger joint” assembly was

chosen. This allowed us to avoid using screws

and to give a nice look to the exterior of the

robot. Of course, to make the case sufficiently

strong, the use of wood glue was considered. On

top of this modification, three panels were

added to house the different mechanical

components and ensure global stiffness of the

robot. The supports for the vertical axis stepper

were designed to be laser-cut in the same

material as the case.