Hand Training Robot

Bruface Mechatronics Team Project

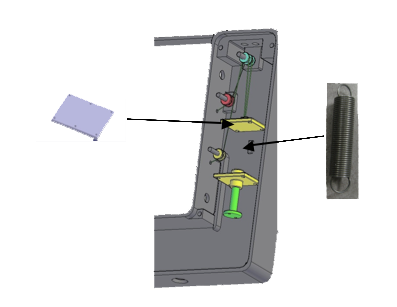

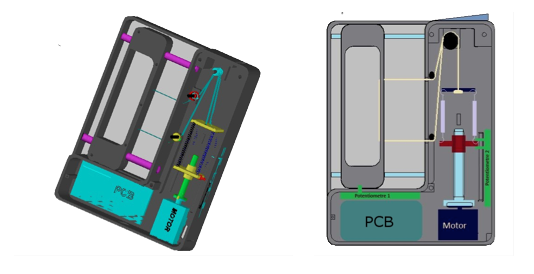

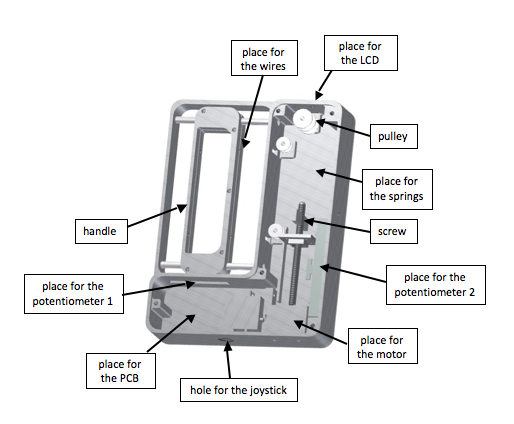

The basic concept is easy to understand: the user has to pull a wire connected to springs in order to train his/her hand. To have a good resistance and to avoid premature wear of the system, we used a kevlar wire and 4 springs connected thanks to a small metal plate.

By changing the elongation of the springs, the difficulty of the exercise would change.

Thus, a servomotor would be used to extend the springs in function of the level the user would choose. In order to do so, a screw is fixed on the motor axis – which is connected to the lower part of the springs thanks to another small metal plate – and the motor has been modified to have a free 360° rotation (the trigger guard on the gears was removed). On this plate, there is a thread hole in which the screw will be able to turn and thus, will be able to adjust the extension of the springs.

Everything is incorporated in a metal box we got back from last year project, and a metal handle is used for the grip of the hand (this handle is of course connected to springs with wires and via 3 pulleys).

To create a more intuitive device with multiple degrees of freedom, the whole box has been mounted on the axis of a joystick; this allows the user to rotate his/her wrist during the utilization and to train better the hand muscles. Let us notice that the axis of the joystick has first been shortened so that the lever arm was not too large and the device was still easy to use and not unstable.

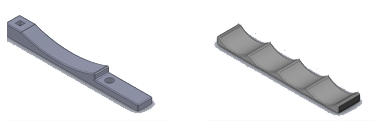

Besides, we wanted to create a device that would be used by left-handed and right-handed people with the same comfort. Thus, two plastic shapes were created with a 3D printer and glued to the handle.

These handles have been stuffed with plastic foam to create a comfortable and ergonomic grip.

Again for ergonomics reasons, a plastic support for the LCD display has been created with a 3D printer. That way, the user has a better vision of the screen, the blinking led and of the information about the exercise session. Moreover, the choice of the parameters with the button and the knob will be easier.

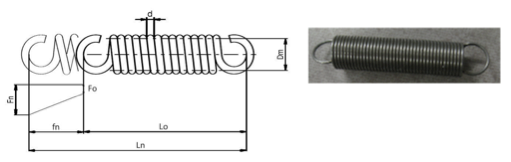

The springs and the motor we used were got back from last year project because of cost considerations. Indeed there was no need to buy new ones since they were still in good condition. Datasheets of both can be found below.

The springs are Alcomex T950 ones:

Those springs are well dimensioned for the usage (large extension for small forces).

The motor is a Futaba S3003: