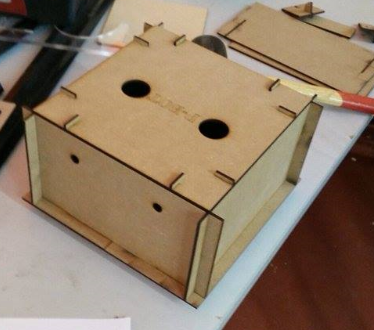

.jpg)

Design

General structure

The general structure was essentially laser cut and designed with Solidworks. The parts were assembled without any screw or glue, instead a 'clicking' mechanism was developed. The plates are made of MDF and have a thickness of 3mm.

All the Solidworks and laser cutting files can be downloaded using following links:

The laser cut plan

2D drawings

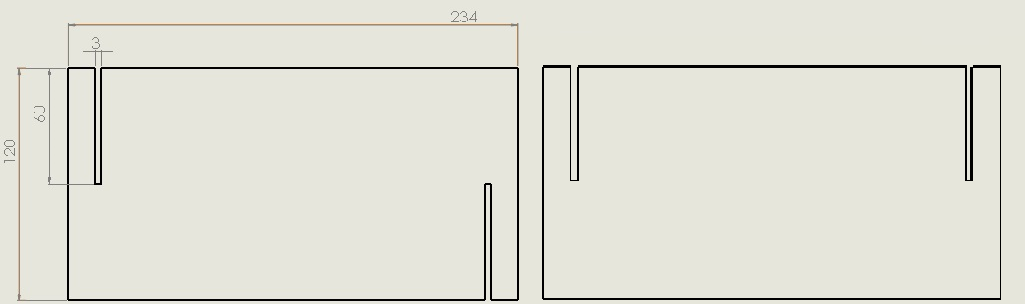

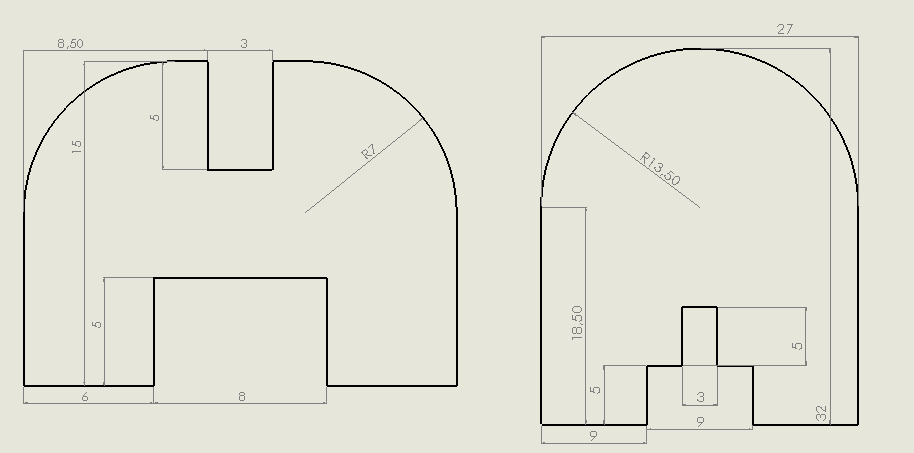

Side plates

The side plates were designed in order to be assembled with the front and back plate without any screws. The two side plates are almost identical except for the cutting made for the assembly. Additional holes were made with a drill in order to pass the axis supporting the wheels and to fix components inside the structure. Those holes were not directly laser cut because the wheels-supporting axis was chosen afterwards.

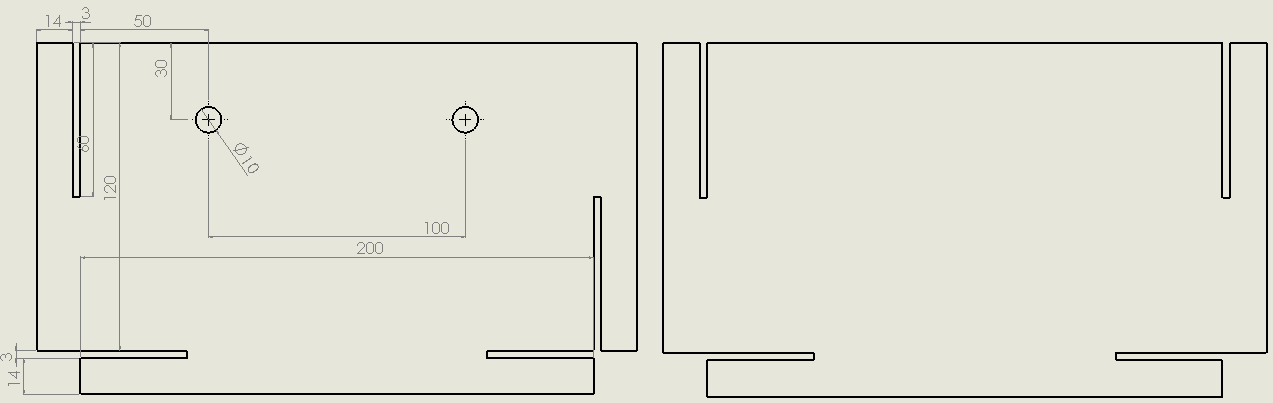

Front and back plates

The front and back plates have additional assembly parts with respect to the side plates. It will permit the two plates of the base to be assembled in a "drawer" mode to the front and back plates. The frond plates has 2 holes for the two LEDS which will light the path of the human who wanders at night.

Base plates

The base will be composed of two similar plates which will be assembled to the front and back plates in a "drawer" way. It has one rectangular hole for the wheel and the part of the gears, one half circle hole for the wire sensors and 4 small rectangular holes for the support of the wheel axis.

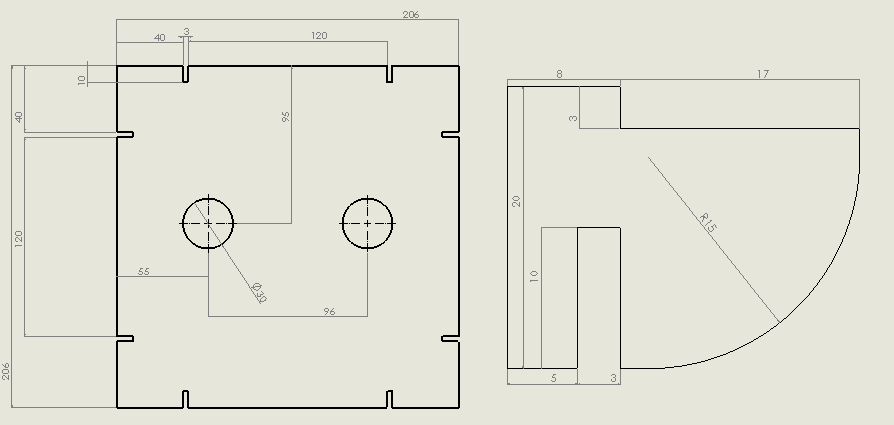

Axe supports

The axis support is composed by 2 small pieces which fit together perpendicularly. This support is then included in the base plate in the 4 small rectangular holes. Additional holes were made with a drill in order to pass the axis supporting the wheels. Those holes were, like mentioned before, not directly laser cut because the wheels supporting axis was chosen afterwards.

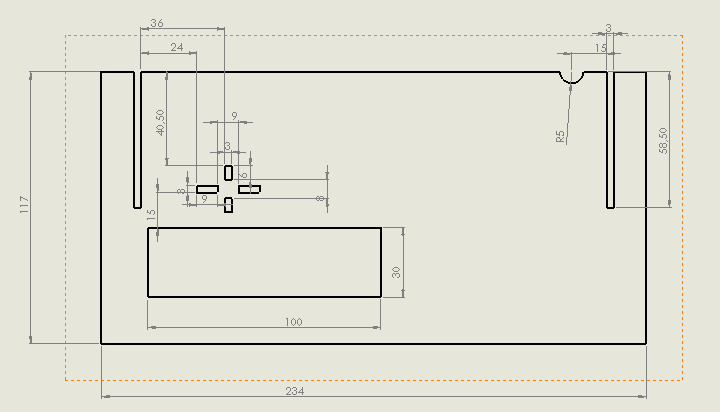

Top plate

In order to remove easily the top plate (to open the robot), two big holes were made. The top plate is maintained on the robot by the help of 8 additional supporting pieces. Those pieces are assembled perpendicularly to the top plate.

This concludes the design and assembly of the robot.