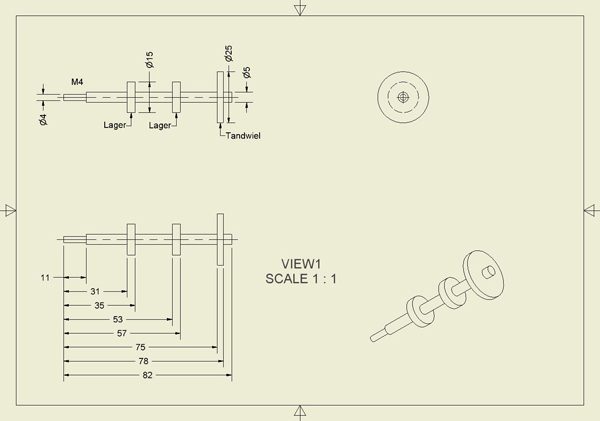

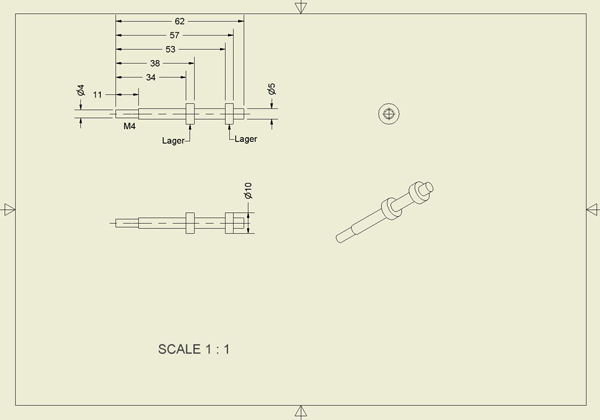

To attach the wheels to the robot, we need axes which are attached to the base using bearings. These axes were manufactured out of brass. This material is easy to process and still is sufficiently rigid and strong. Below you can find the different technical drawings to manufacture the axes. The first drawing is the design of the drive shaft. These shafts also contain the gears that take care of the transmission between the engines and the wheels. You'll need two of these. The second drawing shows the design of the other axes. The robot requires 6 of those. So why use a total of 8 axes and not 6? The permanent magnets are pretty strong and the attracting force to the wall is quite big. This means that the middle of the base plate is pulled towards the wall. We use two extra wheels on the side that drive on the vertical plane. This way we want to give some extra support to the base plate on the vertical wall, to make sure that it doesn't deform too much and that the permanent magnets maintain a constant distance to the wall.

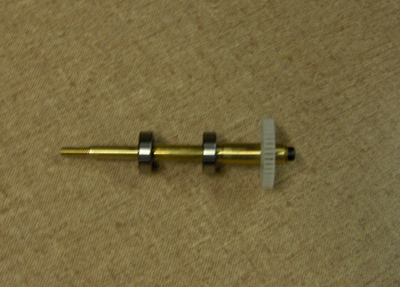

A picture of a drive shaft, fabricated out of brass.